Understanding Merkava 4 armor protection. Part 1 of 3

EDIT: added an illustrative schematic in the KE protection section.

Introduction

The Merkava family of tanks is one of the most unique among modern tanks. Its latest incarnation -and quite possibly, the last-, Merkava 4 represents the culmination of a design philosophy. Whereas the evolution from Merkava 1 through Merkava 3 was done in a more piecemeal fashion (that is, upgrading individual components or areas from the tank from model to model), Merkava 4 is a whole new clean sheet design, that only shares with a predecessor the weapons, both Main Gun and machine guns, making it unique even among its family. That uniqueness has made several aspects of the tank difficult to comprehend. In the present article we aim to analyze a particular aspect of the tank, that being its armor. We will not delve into the protection of the tank considered as a whole. Instead using photographic evidence, patents published by Rafael Systems over 20 years ago (and for some reason apparently unknown to the overall tank enthusiast community) and historical accounts we aim to present as in depth a picture of this tank's peculiar armor as possible. Given the extent of the issue, I will divide this article in 3 parts. Part one covering the front armor (hull and turret) and also the side turret armor module. The side hull armor and roof armor will be left for parts 2 and 3. I´ll keep updating this article as new information becomes public.

For this first part of the article we'll rely mainly on two patents, US7360479 and EP1605224A2 published by Rafael in 2006 and 2005 respectively. While the reader may be familiar already with the former -as its the patent that revealed the specifics of advanced reactive armor such as NxRA or SLERA (we´ll go into more detail about this)- the latter might be completely unknown. In fact, surprisingly, I´m not aware that this patent has come to the attention of any part of the tank enthusiast community during all these years. Briefly, I´ll demonstrate that Merkava 4´s turret and front hull armor modules are made up of 2 different armor types combined working together in the same module. Depending on the type of munition hitting the tank, the same armor module will work differently. Against kinetic energy threats, the armor will work fully passively to absorb, destabilize and deform the penetrators while against hollow charge munitions, the reactive elements of the module will detonate, hence working more like Explosive Reactive Armor (but not really).

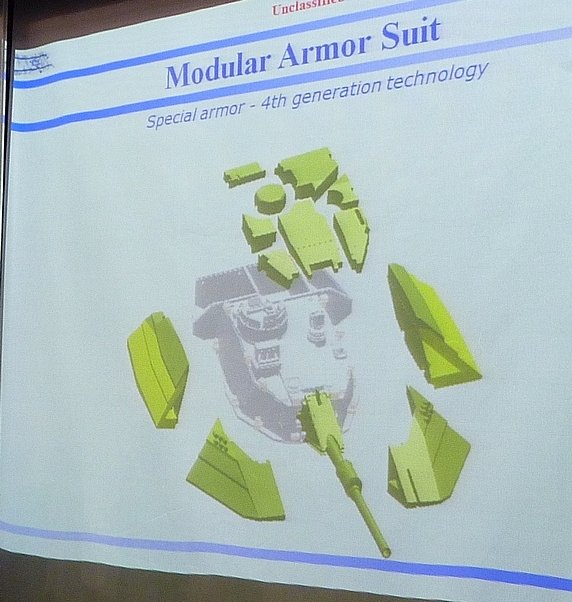

Let's start with the most basic details. We are talking about the heaviest MBT in service today. Merkava 4M weight reaches a whopping 80 metric tons, limiting its tactical mobility with a top speed of 60km/h, well behind most of modern tanks. This much weight is explained mostly by the tanks protective features, including its armor. Merkava 4 armor is unlike any other modern tank. Usually, modern tank armor modules comprise a cavity formed between a front and backplate, and inside that cavity arrays of composite elements are placed. The front plate protects the array from the environment, explosions and the like, the internal array degrades and destabilizes a projectile passing through, and the backplate catches the fragments. Well, this is not the case with Merkava 4. There is no built in cavity in the structure of the tank filled by an internal array. Instead, all the armor is externally mounted in the form of easily removable modules. In fact, in the IDF the armor is known just as “Shiryon Ryaktivy Modulary” (“שריון ריאקטיבי מודולרי”), ie. Modular Reactive Armor, which doesn't say much. The modules are meant to be replaced after taking battlefield damage and that's even more understandable in light of how they are supposed to work. Nevertheless, this is how the armor modules look like:

In this part of the article, we will focus on the modules covering the front and sides of the turret and the front of the hull.

Photographic evidence

Now we´ll continue examining different pictures of the modules in question. We can divide them in two categories: those who have labels warning of explosive elements (“

”) and those who don´t. The first category encompasses front and side turret armor modules and also the armor modules on the fenders at the front hull. The front hull armor modules directly above the powerpack don´t have such label.

Pictures of battle damaged modules allow us peek into the interior structure:

We can see here that the interior structure of this module comprises sandwiches of thinner elements bolted on a thicker plate. So in order we would have a very thin sheet acting as a cover plate to protect the interior elements from the environment, a flyer plate likely of comparable thickness as previous models by Rafael (could be about 5mm), a layer of reactive element, a rubber or kevlar element acting as cushion, the thick plate and then another later of kevlar or rubber like material. The following sandwiches should have the same composition except for the thin sheet cover plate.

There are at least 2 and most probably 3 of these sandwiches at the straight front section of the module, all sloped at about 72º. Meaning, there could be at least 3 flyer plates at the line of sight at any point of the module. I´ve estimated that the module has about 800-830mm of thickness at the line of sight, inside of which the sandwiches are likely arranged in the following way:

Looking at the same module but from the more diagonal area, we see a slightly different internal composition. Here we can count up to 4 thicker arrays and a thinner one at the back. These 4 are most likely the same sandwiches described above in the straight front section. The 4rth array is then likely for compensating the less sloped angle of these (about 66º). At the back we find a thinner layer that is probably just a flyer plate with reactive element layer and some structural support:

It's possible that the straight front section also has a 4th flyer plate arranged in the manner behind the 3 sandwich-like arrays, but we don't have definitive evidence.

The different composition when compared to the front module points to different protection capabilities for each module. This will become clearer in the next sections.

Next we have the front hull modules. The only modules here that have the ´explosives´ warning labels are the ones installed on top of the tracks. The modules directly above the powerpack don´t have such labels although the flyer plate arrangement is visible.

This image was shared initially by Mighty Zuk

This image was shared initially by Mighty Zuk

Its possible that each of these modules have different constructional thicknesses, with the ones closer to the crew being thicker. It is both possible and probable that these modules comprise each of 2 “sandwiches” with flyer plates bolted on top of Orlite plates. However I will caution that as likely as that seems so far we don´t have evidence of Orlite composite plates there so this will remain just as speculation for the moment, however the presence of flyer plates is clear. Given that there are flyer plates but no explosive elements, its all but confirmed that these front modules utilize a form of Non-Explosive Reactive Armor (NxRA), which will be described in the following section.

CE protection

At this point it could be argued that the fact that Merkava 4 is covered by flyer plates pretty much everywhere point to wide usage

of Explosive Reactive Armor (ERA). Indeed, reactive armor using flyer plates remains the most efficient method for defeating

shaped or hollow charge (HEAT) threats. After all, the IDF was the first army to field ERA back in the 1980s. For the uninitiated,

it works the following way: HEAT warheads upon detonation form a jet of molten lead traveling at insane velocities

(about 5000-6000 meters per second) that pierces through plain steel armor very easily. However, when coming into contact with

a reactive element, its detonation displaces the flyer plates. The interaction between the HEAT jet and the flying plate erodes and

diffuses the former, weakening it to the point its incapable of piercing through into the crew compartment of a tank.

Helte, Lundgren and Candle (2024)

However there are key elements that disprove this possibility: ERA needs to isolate each of the explosive reactive elements

from each other. Hence these armor types are built in the form of bricks. Each of the bricks has their own explosives and flyer

plates. The separation between the explosive elements (necessary to prevent sympathetic detonations) creates weak points,

any HEAT jet passing through won´t activate any ERA brick. However in the case of Merkava 4 we don't see any separation

between flyer plates nor any kind of compartmentalized brick arrangement. The flyer plates are bolted on top of a common

structural element, one next to the other. That means the reactive element propelling the flyer plates isn't a traditional

explosive. Which leads us to the main source for this section: Patent US7360479 “NON-EXPLOSIVE ENERGETIC MATERIAL

AND A REACTIVE ARMOR ELEMENT USING SAME”

This patent is relatively known among the tank enthusiast community. It classifies reactive armor into for main categories:

Explosive Reactive Armor (ERA), Non Energetic Reactive Armor (NERA), Self-Limiting Explosive Reactive Armor (SLERA) and

Non-Explosive Reactive Armor (NxRA). We have already described ERA: consisting of at least 1 flyer plate that is propelled by

an explosive that detonates as it comes into contact with a threat. NERA on the other hand is fully passive. Instead of an

explosive, the steel plates have elastomer-like elements sandwiched in between. The energy of the threat projectile (be it a

kinetic energy or a HEAT-produced jet) strikes the array and causes it to bulge in response. That movement erodes the threat.

These two armor types are the oldest among reactive armors and have been present in one way or another in most of the

modern tanks since the 1970s. The patent focuses instead on SLERA and NxRA and especially on the latter. These 2 are

described very much like ERA, the main difference being that they don't use conventional explosives as reactive materials.

And the main difference between SLERA and NxRA is that the former´s reactive material still can be classified as an

explosive (though not conventional) while the latter can´t, it uses a mix of elements which upon interaction with a threat act

as a gas generator which propels the movement of the flyer plates.

The patent characterises the different reactive armors according to 2 criteria: threat defeat efficiency (how efficient is the armor

mass/volume wise for defeating threats) and multi-hit capability (how many hits can the armor take before becoming non

functional). In the first criteria, the armors score from better to worse in the following order: ERA, SLERA, NxRA, NERA. Its to be

noted that SLERA and NxRA are stated to be relatively close to ERA threat defeat efficiency. On the multi hit capability, the

armors score from better to worse in the following order: NERA, NxRA, SLERA and ERA, ie. just the opposite. An ERA brick can

only detonate once while NERA can protect against a great number of threats. NxRA is described as comparable to NERA in

this aspect while SLERA´s multi hit capability is described as “good” as long as it is arranged in a modular scheme.

Given the layout of the flyer plates on Merkava 4 and the presence or absence of labels warning of “explosive” elements in each

module, the logical deduction is that the modules covering the tank´s powerpack can be classified as NxRA armor while the rest

(hull fenders, turret front and side) are of the SLERA type. Given that SLERA has better threat defeat capability and that

Merkava 4 modules are meant to be quickly replaced after sustaining combat damage, why use NxRA on the hull front? The only

possibility I can think of would be security concerns, given that there is no physical separation between the module and the

powerpack beneath, with all its combustible fluids perhaps using a non-explosive element is perhaps safer to a point.

KE protection

I will start this section on a short personal note. The discovery of patent EP1605224A2 was one of the main motivations for

writing this article and the final push I needed to finally decide on starting my own blog. As it happens, the KE protection

capability of Merkava 4 is a very debated aspect through the tank enthusiast community. A good portion of it argues that the

tank was meant mostly to fight infantry elements in asymmetric warfare scenarios, in other words, protection from enemy

tanks likely wouldn't be a high priority. Those who argued otherwise were so far missing a source to substantiate their

position, that is until now. Patent EP1605224A2 is the first solid source supporting the idea that Merkava 4 indeed does

feature protection against modern APFSDS.

The patent EP1605224A2 “A passive armor assembly including an armor member made of a brittle material” was

published back in 2005, at the same time the previous patent and also the same time Merkava 4 started to be produced

serially although at very limited numbers initially. The patent describes a fully passive armor explicitly meant to defeat KE threats,

and more specifically modern 120 or 125mm APFSDS featuring long rod penetrators (LRP) using non metallic plates. But can we

relate this patent to Merkava 4 armor, even ignoring the historical context? Well going by the description of the invention, the

materials used by Orlite and the photographic evidence I'm inclined to believe that the answer is as positive as it can be under the

circumstances.

“The present invention provides a passive armor assembly for protecting a body disposed behind said armor assembly

from an impact of a long rod penetrator (hereinafter LRP), said armor assembly comprising (i) an armor surface that is

capable of exerting asymmetric forces on the oncoming LRP and (ii) an armor member made of a high compression

strength, low density, brittle material, said armor member being disposed behind said armor surface and having a thickness

along the direction of said impact, which exceeds the length of the LRP. Preferably, the thickness is at least 1.5 or

more the length of the LRP.

The armor member may be made of a single body (monoblock), may be made of several layers of smaller thickness

adjacent to each other, or may be made of separate sub-members. Such layers may be attached to each other, for instance, by a suitable adhesive, but this is not a necessity. Preferably, the thickness of each of the plurality of layers composing the armor body is at least about 20mm.

As shown above, these are exactly the materials Orlite makes its composite plates off.

If we accept that these composite plates are the realization of the described passive

anti-KE armor, we can continue to the details of the defeat mechanism:

“Without being bound to theory, it may be assumed that disruption of an LRP by

an armor assembly according to the present invention may be caused by the

combination of at least the following factors:

1) The armor surface causes the penetrator to impact on the armor member

asymmetrically, creating in the armor member an asymmetrical penetration crater.

2) The brittleness of the armor member preserves the asymmetrical nature of the

penetration crater.

3) Due to low damage velocity of the armor member and its relatively large

thickness, non-damaged portions of the armor member constantly exert on the

penetrator asymmetric forces. Since the penetrator is constantly in an asymmetrical

crater, the forces acting on it all along the way are asymmetrical, such that they

eventually cause it deformation or breakage.

Since the penetrator is long, the armor member exerts different (asymmetric) forces

at different times on different portions of the penetrator, and thus tends to enhance

the deformation of the penetrator as it advances inside the armor member, and

even brings it to breakage. The longer the penetrator, the greater is the number of

its potential breaking points.

The main mechanism that causes the LRP to loose momentum is increase of surface

area in the impact direction, caused upon deflection, deformation or breakage of the LRP”

So we have a clear explanation of how Merkava 4 KE protection likely works. The Orlite manufactured composite plates don´t only provide a structure to which the SLERA/NxRA flyer plates can be bolted on (in such case one could wonder why these plates are only present on the frontal aspect of the tank and not on the side modules as well), but they are the central element for defeating APFSDS and protecting the crew against these.

By the description above, the effectiveness of this armor is mainly limited by volume or physical thickness through the path of the projectile. Given that the physical thickness of the front turret armor is about 800mm or a little more, and the front hull is more than 600mm, we could prematurely conclude that these could defeat penetrators of about 533mm and 400mm long respectively. However this would be premature and wrong since the modules aren't a single piece of PMMA-like material (ie. Orlite composite), they have several other elements inside, flyer plates, reactive materials, and empty air.

So the actual thickness at LOS of the PMMA-like plates is actually less, pushing the limits of protection even lower. However the patent describes a very specific reference threat its meant to protect against:

“Long rod penetrators fired by guns are commonly just 6-25mm in diameter, and 100-600mm long. To maximize the amount of kinetic energy released on the target, the penetrator is normally made of a hard and heavy material, such as steel, tungsten alloy or depleted uranium.

It is generally accepted that long rod penetrators are one of the most effective ammunition in penetrating armor today. They are typically fired at velocities of between 1000 and 1800m/s.”

So the patent states explicitly that its meant to protect an object, such as tanks, against

APFSDS whose penetrators are up to 25x600mm long and traveling at velocities up to

1800 m/s. There seems to be a contradiction between the threat described and the

volume limits of the Merkava 4 armor modules. However the patent also describes several

ways to enhance the volume efficiency of this type of armor, since the patent describes

several embodiments of the armor other a single piece of PMMA-like material. One of

these is a multi layer approach, ie. the PMMA subdivided into multiple sub members

spaced between each other:

Now this resembles the interior structure of Merkava 4 front armor modules a lot more. It is described as follows:

“Fig. 3 schematically shows a passive armor assembly 2 according to another embodiment

of the invention, where the armor surface 8 is made of three discreate sub-members 12A,

12B, and 12C, having thickness of 𝜏A, 𝜏B. and𝜏C, respectively, such that 𝜏A + 𝜏B + 𝜏C = 𝜏.

𝜏 should be at least equal to the length of a penetrator from which protection is sought. Upon impacting an armor assembly according to such an embodiment, an oncoming LRP

meets a slanted armor surface a plurality of times, and asymmetric forces act on it once and

again. Such an embodiment may be of particular advantage in protecting against LRPs

with spherical or flat heads.”

Note that using this spaced arrangement, the minimum physical thickness required to defeat

a penetrator came down from more than 1.5 times its length to being equal to it. The effect

this array has on an APFSDS is shown in the patent:

So in abstract we can already argue that if we can fit 600mm LOS worth of Orlite plates

inside Merkava 4 armor modules, the protection against the reference threat should be

already guaranteed. Using the three layers described above, each 60mm thick and spaced

between each other at 40mm, we have a total of 260mm that translates to about 841mm

LOS (at 72º), which is within the margin of error of the measurement we made on the

front turret module. In the case of the front hull, we could fit 2 physical arrays separated by a

single empty space (160mm in total), sloped at 74º it yields 580mm, so it can absolutely fit

in the more than 600mm available.

Turns out that NxRA and SLERA are stated to provide protection against APFSDS as well:

“According to the present invention there is provided a NxRA element with a non-explosive energetic material of the above type for protection against shaped-charge warheads, as well as against small arms, shrapnel, fragments and various types of kinetic projectiles, e.g. Armor Piercing Fin Stabilized Discarded Sabot (APFSDS).

...

A reactive element according to the invention (NxRA) is efficient against shaped charge warheads, giving as an example RPG 7, as well as against various types of kinetic

projectiles, e.g. APFSDS, small arms (e.g. 14.5 mm), shrapnel and fragments. A NxRA element according to the present invention provides comparable efficiency to SLERA as discussed hereinabove, as well as comparable survivability to NERA. The NxRA element is advantageous over other reactive armor technologies as it is totally passive, as NERA, and it offers improved survivability to the protected enclosure, to neighboring reactive elements and further provides excellent multiple-hit capability against hollow-

charge warheads, small arms and kinetic projectiles and eliminates fragmentation hazards.”

So, KE protection coming from SLERA/NxRA is provided but sadly the patent doesn´t go into

further details, such as the exact threat defeat mechanism. However it may be possible that

these reactive armors are meant to act just as passive, extra steel plates since the sensitivity of

reactive elements can be adjusted to detonate only when in contact with HEAT jets. Such a

solution was already applied in a previous form of ERA also developed by Rafael and disclosed

in patent EP0379080B1 (“A combined reactive and passive armour”). This patent was filed in

1990 and published in 1996, and it could be attributed to some armor elements present on

Merkava Mk.3. Perhaps one day I´ll write about this issue but not today. Nevertheless, the

patent states:

“It has been found in accordance with the present invention that a reactive armour made of elements

of the kind specified, is also effective against armour-piercing kinetic energy projectiles such as,

for example, sub-calibre projectiles and armour piercing bullets even when such projectiles do not initiate

the reactive armour.

In such a situation the metal plates of an associated pair of protective assemblies produce an augmented

spaced armour effect which is an aggregate of the effects pro duced by the plates of the two assemblies

and is significantly larger than in conventional reactive armour where a similar effect is produced by only

one or two plates. Thus, in this way the impact of a kinetic energy projectile is also mitigated in accordance with the invention,

which is a significant improvement over conventional reactive armour which is designed not to be initiated by

kinetic energy projectiles.

...

A reactive armour according to the invention is also effective against armour piercing kinetic energy projectiles.

Such projectiles will, as a rule, not initiate the explosive layer of the reactive mass and energy absorbing

assemblies 8, 8'. This is so because in accordance with the present state of the art the layers 1 0 and 1 0' are,

for reasons of safety, constituted by an explosive with a high initiation threshold. However the metal plates 11,

1 2, 1 4 and 1 5 and 1 1 ', 1 2', 1 4' and 1 5' produce a spaced 25 armour effect which may further be enhanced

by swelling of the swellable material 13, 13' and in this way the penetration capability of a kinetic energy projectile

is significantly attenuated”

This could perfectly be the case for SLERA and NxRA as well in Merkava 4, which are further developments of

the above described Explosive Reactive Armor. However when looking at the internal array of Merkava 4 front

modules we find that the amount of flyer plates may not contribute much. Assuming there is a single flyer plate

bolted on top of each Orlite plate, on the front hull we are talking about 2 flyer plates (which already should

defeat tandem CE warheads), and 3-4 on the front turret module as there are likely no more than 3 sandwiches

on the straight front and 4-5 on the more diagonal sector of the module. If each flyer plate has a thickness of around

5mm (which would be consistent with previous ERA designs) then we are talking about 36mm of steel at LOS on the

hull and 50mm on the turret. Of course the spaced effect would yield higher performance than the simple sum of

physical thickness but these thin flyer plates are likely not efficient against 120-125mm APFSDS. However with the

side turret module it's a different case since it has about 9 flyer plates sloped at 63º, that in practice is 99mm of steel

at LOS without accounting for the spaced layout and the thickness of the base turret structure. In other words, the SLERA side turret module indeed does provide protection against medium caliber kinetic rounds, especially the full bore type that is so common in soviet 30mm used on BMP-2.

However, is just acting as extra spaced steel the only thing the flyer plates bring on the table for the front modules? No, and EP1605224A2 might indicate a second function for these flyer plates as additional “armor surface” placed on top or in front of the Orlite plate, enhancing the volume efficiency of the array as a whole:

“The armor surface may be, for example, the outer surface of the armor member, attached thereto, or separated therefrom.

According to one embodiment, the armor surface is disposed in front of the armor member, preferably parallel thereto, and the distance between the armor surface and the armor member is at least 5mm, preferably 10mm or more.

...if the armor surface is made of a metallic material, the effect the assembly has on the penetrator is particularly strong. This is so although the ductile surface is thin enough not to have a protective value by itself...This may be of particular usefulness if the penetrator, from which protection is sought, has a hemispherical or flat head.

The armor surface of the invention may be advantageously covered with a front non-armor layer for protecting it from environmental hazards, such as blows, humidity, irradiation, and extreme temperature.

Such a non-armor member may be made, for instance, from a thin layer of 4mm aluminum, 10mm KevlarTM, or steel with similar areal weight. “

The last section suggesting a covering non-armor layer for the module is also another indicator that we are indeed talking about Merkava 4 modules. In addition, keep in mind that from photographic evidence we can see another layer of material bolted behind the Orlite plates:

“To increase the volume efficiency of an armor assembly according to the invention it may be advisable to include in the armor assembly, behind the armor member, a backing layer of ductile material in order to absorb momentum of the LRP or its pieces as they exit from the back of the armor member, or make them ricochet from it. This may allow using an armor member of smaller thickness without compromising the degree of protection. In some cases, this may also allow to have armor assemblies with higher weight efficiency than may be designed without such a ductile backing layer. In some cases, the function of such a backing layer may be fulfilled by a wall of the body to be protected.

Non-limiting examples of ductile materials, as this term is used all along the present description and claims include ductile metals, such as steel and aluminum, and composite materials, such as high-density polyethylene or aramid fibers or fabric, as those commercially available under the trade-names KevlarTM or Dyneema.”

In sum, the arrangement of the Orlite composite in multiple spaced plates together with extra elements acting as armor surfaces (flyer plates) and backing layer (the unidentified layer bolted on the back side of each Orlite plate) enhance the volume efficiency of the array as a whole perhaps even allowing the defeat of penetrators longer than the sum of PMMA-like material they encounter at LOS. At a bare minimum, protection against the specified reference threat (that is, an LRP 25x600mm long fired at 1800 m/s) should be achievable.

Armor protection assessment

Using as reference the array proposed in Fig.3 of EP1605224A2 (60mm PMMA-like layers separated by 40mm of air)

we estimate a total thickness of 580mm of composite material. The more lateral sector of the front array achieves

590mm using a 4th Orlite plate which compensates for the decreased slope (66º). Since we are not able to mathematically

estimate the added efficiency of armor surface and backing elements we can safely suggest that this is enough at least to

defeat penetrators 600mm long and perhaps even longer. However flawed the numerical representation of penetration or

RHA armor equivalency, we can still propose some figures.

To calculate an absolute baseline we take only the LOS amount of Orlite composite material. This would be 580-590mm for

the front turret and 435mm for the front hull (assuming 2 composite plates). If we model theoretical projectiles that have an

L/D ratio of at least 24, since that is the ratio proposed in the 25x600mm reference threat specified in the patent in question,

we arrive at the conclusion that the minimum LRP that can be defeated by the front hull is 18x435mm while 24.5x590 corresponds

to the baseline limit for the front hull. The last step would be to assign an impact velocity that's slower than 1800 m/s since

that's the stated muzzle velocity. If we assume a rather safe impact velocity of 1700 m/s we arrive at a protection value of at least

480mm (equivalent to RHA sloped to 60º and 413mm if sloped at 0º) for the front hull and 655mm for the turret front (equivalent to

RHA sloped to 60º and 560mm if sloped at 0º) , across a wide arc. If instead we use the larger reference threat round (25x600mm)

with the same impact velocity then we have an equivalent of 666.6/570mm (at 60º and 0º) of protection to be provided at least by

the turret front.

A couple of notes before going to the conclusions segment. I repeat yet again that the above estimations don´t account for the

efficiency enhancing effects of the armor surface and backing elements present on the array yet these are figures that I feel

comfortable with since for the moment we have not absolute clarity about the internal composition of the armor modules nor

precise measurement of their external dimensions. Secondly, the value calculated for the front hull also doesn´t take into account

the powerpack compartment which acts as a huge spaced armor array, so that value could correspond to the penetration of munitions

that the module can stop by itself. The added effect of the powerpack compartment (and the sacrifice of the powerpack itself in case of

penetration) could yield significantly better results so its not impossible at all that the crew is also protected against the reference threat

rounds if they hit the tank on the hull front as well.

Estimating CE protection is more complex. But for starters, the presence of at least 2 flyer plates on the hull and many more on the turret at any point should guarantee protection to the crew against tandem HEAT warheads. The problem lies instead in estimating the caliber of warheads that each module protects against. We know from battlefield records in Lebanon 2006 that Merkava 4 were prioritized and engaged almost exclusively by Hezbollah using Kornet ATGMs (as recounted here https://yadlashiryon.com/armor_wars/the-second-lebanon-war/ ). We have photographic evidence of Merkava 4 impacted frontally most likely by a Kornet and not producing a penetration, which means that at least the front turret provides protection vs 152mm tandem warheads, rated as 1200+mm of penetration. It's possible that the larger number of flyer plates placed on the side hull module provide such a high level of protection as well. Perhaps after the war in Gaza is over and data is released we´ll get much more clarity, but we have seen Hamas militants scoring hits on Merkava 4 tanks on the sides utilizing 105mm tandem warhead “Yasin” rockets and failing to penetrate. Time will tell.

Summary and conclusions

1- Merkava 4 turret front was adequately protected against KE projectiles for its time. With 650-700mm

of effective KE protection, it was very well protected against the likely threat APFSDS of the 90s and

early 2000s. The reference characteristics mentioned in EP1605224A2 (600x25mm at 1800 m/s) are

very close to KEW-A1 (600x26mm at 1740 m/s), a licensed DM43 by General Dynamics, which was

the best APFSDS available to Egyptian Abrams in early 2000s. This protection level also effectively

protects vs whatever Jordanian or Syrian tanks could/can fire.

2- This protection level is also coincidentally very comparable to NATO´s mid 90s requirements

(650mm KE according to British sources, corresponding to Leo 2A5 and M1A2), which was the

development period of Merkava 4.

3- However this is no magic armor. Specifically, the efficiency is volume limited and the armor will start

growing increasingly inneficient as it deals with penetrators longer than 600mm. Hence, against the more

modern APFSDS (DM53 and others), protection at close combat ranges isn´t guaranteed (perhaps can only

resist these starting at 1,5-2km). It can´t be coincidence that after Svinets was put into production in Russia

some years ago, Rafael unveiled newer models of ERA focusing on KE efficiency.

4- This limit regarding efficiency depending on the length of the penetrator is more critical when it comes to

the front hull protection. By itself, the UFP (480+mm KE) can only resist some of the older APFSDS, back from

the 1980s. Against anything newer, the powerpack compartment will act as a giant spaced armor cavity (ie.

sacrificing the powerpack but saving the crew). However as with the turret, against the more recent projectiles,

protection isn´t guaranteed.

Sources

Helte A., Lundgren J. and Candle J. (2024) “The interaction between a shaped charge jet and a single moving plate”.

Defence Technology Volume 31, January 2024, Pages 1-1. Available at: https://www.sciencedirect.com/science/article/pii/S221491472300185X

EP0379080B1 A combined reactive and passive armour. Available at https://patents.google.com/patent/EP0379080A3/en

EP1605224A2 A passive armor assembly including an armor member made of a brittle material. Available at https://patents.google.com/patent/EP1605224A2/en

US7360479 Non-explosive energetic material and a reactive armor element using the same. Available at https://patents.google.com/patent/US7360479B2/en

https://www.youtube.com/watch?v=cRW1aO4DxoQ&t=4s&ab_channel=ArmoredcorpsIdf

https://yadlashiryon.com/armor_wars/the-second-lebanon-war/

Comentarios

Publicar un comentario